The Maintenance Steps Of Electroform

Description

When electroform is injection-molded, the LENS might oxidize due to oil stains and other impurities, and the non-glossy oxides will be generated on the electroform, which will lead to rust or oxidation. Maintenance work can extend life of electroform.

Maintenance on the Mold

a. Before injection molding, please use an air gun to spray the surface of the electroform to remove oil, impurities or foreign matter.

b. Then use organic solvent (acetone, stain removal oil) and brush to remove rust-proof oil.

c. Finally, spray the surface with air gun, and check whether there are oil stains or foreign matter residues on each reflective surface, prevent scratches, adhesion or oxidation on the surface due to oil stains or residues after injection molding.And do not perform molding work until the anti-rust oil has been completely removed.

d. After the injection molding is completed, spray the residual material on the surface with air gun, and then clean the surface of the electroform mold core with acetone or degreasing oil.

e. After the final spraying of vaporized anti-rust oil, store the mold to avoid rusting.Do not use white emulsified mold maintenance spray

Note: Do not use chloride ions (mold lotion, WD40 and other organic solvents) to clean electroform to prevent serious corrosion.

Cleaning methods and instructions

a. Use the back end of paint brush, as shown below

Cut off the softer bristles at the end and cut them to flat, use the hard at the root to apply.

b. When cleaning, please use air gun to clean the surface, avoid scratching the surface of the electroform due to residues, impurities or dirt during brushing.

c. Soaking in toluene: When the surface of the electroform is dirty and cannot be cleaned by the above two methods, it can be soaked and dissolved in toluene for a long time.

Note: Acetone or toluene are high volatile agents. When using it, any fireworks must be strictly prohibited, and electrical appliances must be turned off.

The problem that the grease and dirt

are not removed after heating

Oil will damage the electroform and even penetrate into the Ni layer to produce non-glossy oxides and cause rust. The surface is uneven, and cannot be repaired.

Oil stains on the surface of PIN become oxides and carbides

Reflector with Oil

Mixing of plastic and impurities scratches the reflective surface and affects the reflection value

Precautions for plastic injection reflector

Precautions for plastic injection reflector The Maintenance Steps Of Electroform

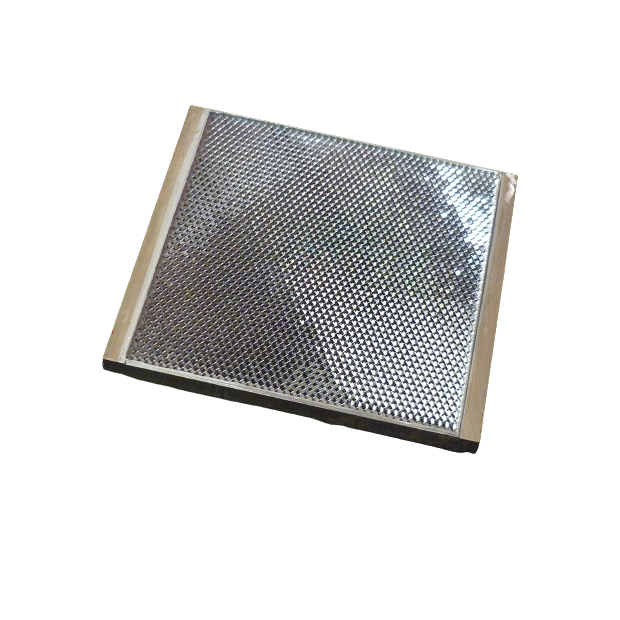

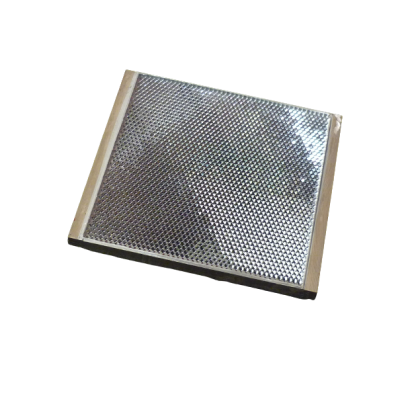

The Maintenance Steps Of Electroform Standard Flat Electroform

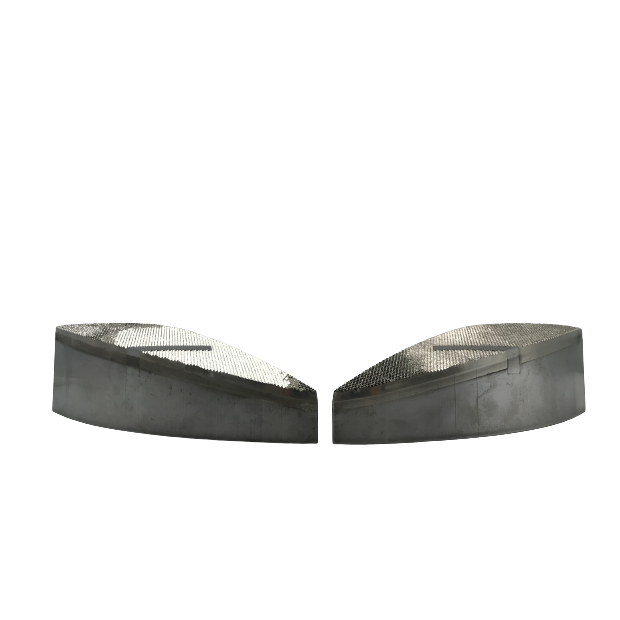

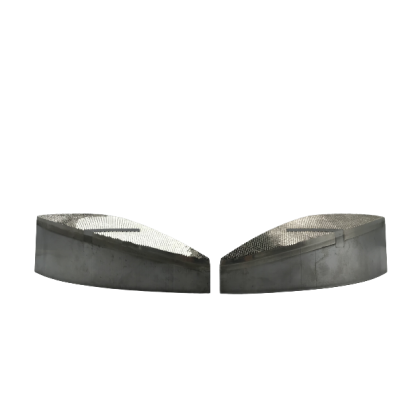

Standard Flat Electroform Customized Curve Electroform

Customized Curve Electroform